郭国娜离子束切割仪英文名字

- 聚焦离子束

- 2024-03-22 07:00:23

- 674

Title: Introduction to Ion Beam Cutter: An Advanced Tool for Material Processing

Introduction:

The ion beam cutter, also known as an ion beam welder or a plasma cutter, is a high-temperature tool that utilizes ionized gas to perform cutting and welding operations. It has gained significant attention in recent years due to its potential applications in various industries, including aerospace, biomedical, and construction. In this article, we will explore the concept of an ion beam cutter and its importance in modern technology.

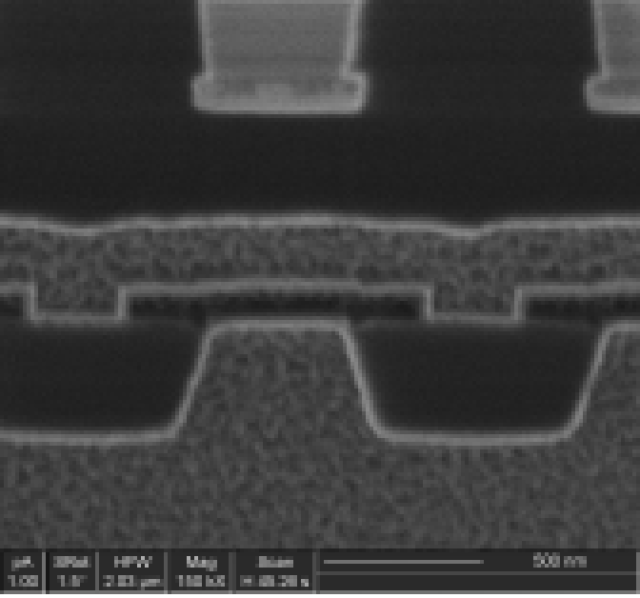

Construction and Working Mechanism:

The ion beam cutter consists of several components, including a high-temperature ion source, a high-temperature gas supply system, and a workpiece holder. The ion source is designed to produce high-energy ions, which are then directed towards the workpiece. The gas supply system is responsible for maintaining the ionized gas at the required temperature and pressure. The workpiece holder is used to secure the workpiece in place during the cutting process.

The working mechanism of the ion beam cutter can be divided into several stages:

1. ionization: The gas is introduced into the ion source, where it is ionized by high-temperature conditions. This creates a high-energy ionized gas that can be directed towards the workpiece.

2. ion extraction: The high-energy ions are extracted from the ionized gas and directed towards the workpiece. This results in a high-temperature plasma arc, which can be used for cutting and welding.

3. cutting: The plasma arc is directed towards the workpiece, where it cuts through the material. The high-temperature plasma arc can cause thermal damage to the workpiece, leading to efficient cutting of various materials.

4. post-cutting: After the cutting process is complete, the plasma arc is directed towards the workpiece to weld the cut edges together. This helps to reinforce the cut material and can be used to create composite materials.

Applications:

The ion beam cutter can be used in a range of applications, including:

1. aerospace: The ion beam cutter can be used to cut and weld materials commonly used in the aerospace industry, such as titanium, aluminum, and stainless steel. It can also be used to join different parts together to create composite components.

2. biomedical: The ion beam cutter can be used to cut and weld materials used in biomedical applications, such as silicone, glass, and metals. It can also be used to create tools and devices for minimally invasive procedures.

3. construction: The ion beam cutter can be used to cut and weld materials commonly used in construction, such as concrete, steel, and aluminum. It can also be used to create tools and equipment for cutting and shaping various materials.

Conclusion:

In conclusion, the ion beam cutter is an advanced tool that can be used for cutting and welding operations. Its high-temperature plasma arc can cause thermal damage to the workpiece, leading to efficient cutting and welding of various materials. It can be used in a range of applications, including aerospace, biomedical, and construction. The ion beam cutter has the potential to revolutionize material processing and can play an essential role in modern technology.

郭国娜离子束切割仪英文名字 由纳瑞科技聚焦离子束栏目发布,感谢您对纳瑞科技的认可,以及对我们原创作品以及文章的青睐,非常欢迎各位朋友分享到个人网站或者朋友圈,但转载请说明文章出处“离子束切割仪英文名字 ”

上一篇

bga封装芯片

下一篇

芯片数据修改校验方法